Add Text Here...

Facilities

Our 30,000sf facility is a campus comprised of 3 separate, neighboring buildings - Inventory control, Manufacturing and Final Assembly/Inspection/Test.

Surface Mount

Yamaha Automated Paste Printing w/SPI * Yamaha Multi Machine SMT Placement lines * BTU Reflow Ovens * KIC Profile Verification

Through Hole

Manual Assembly Lines * Lead / Lead-Free wave solder * Pillar House selective soldering Lead / Lead-free

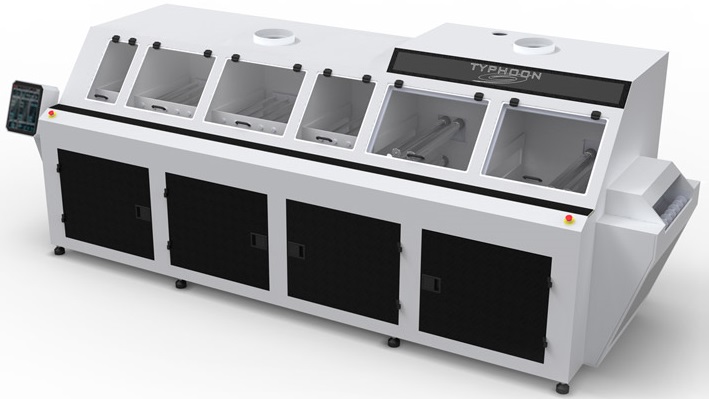

Cleaning

Aqua Klean Inline PCB cleaning systems

Inspection

VisCom AOI (Automated Optical Inspection) * Dage X-Ray Systems * Omron X700 AXI (Automated X-Ray) * Vision Engineering Inspection Scopes * Hakko Solder stations

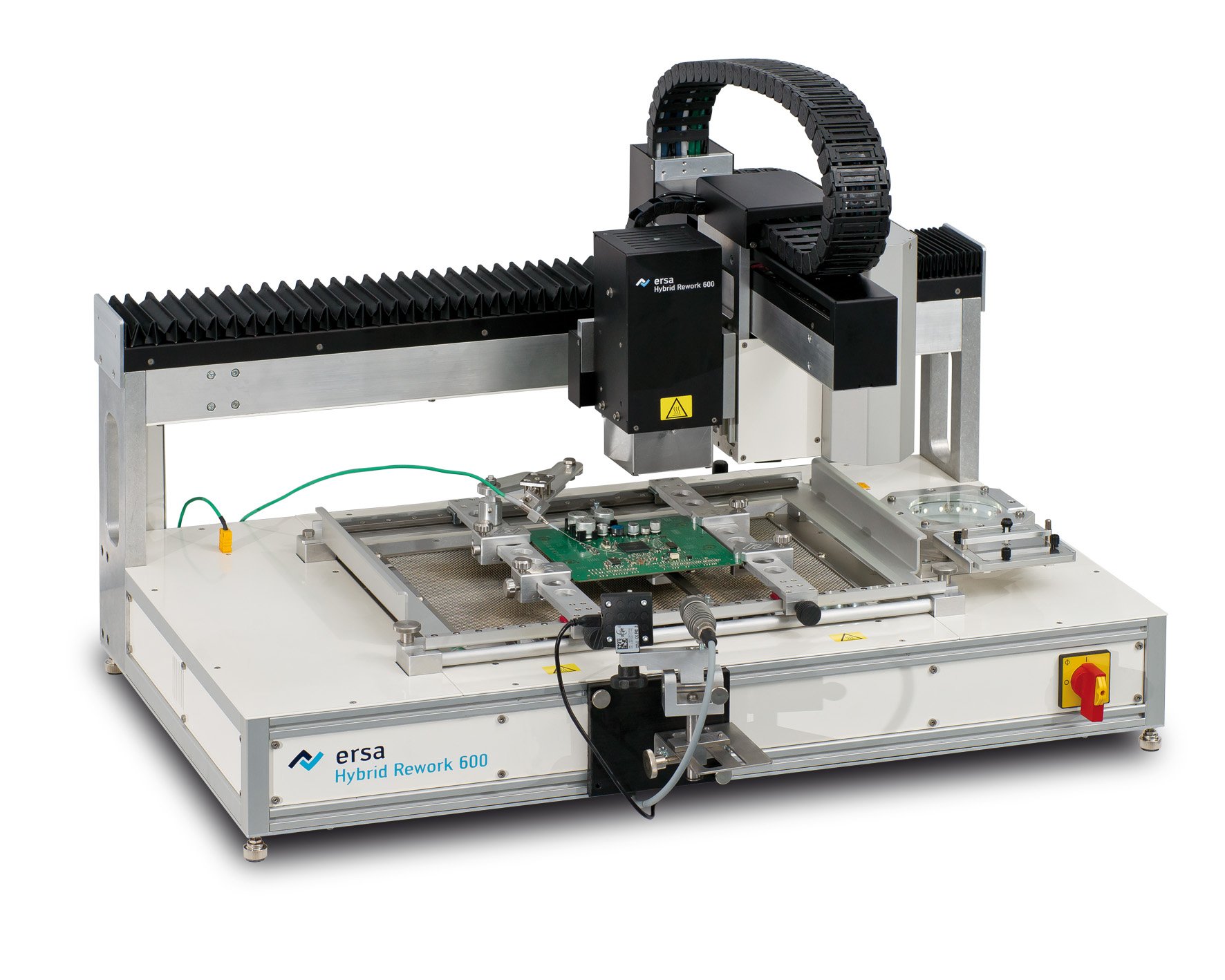

Test & Repair

Functional Testing & Data Tracking * PDR Infrared rework stations * Ersa Automated rework system